Digital printing is a four color process (plus white), high definition 1200 dpi that is capable of hitting over 10,000,000 colors.

It’s a digital world. We are just living in it.

Everything has gone digital today, from cameras to printing, and for good reason. Digital processes just offer too many advantages to ignore. So it’s no wonder why so many of the world’s 10,000 printing lines (20%) have already made the switch to digital. Another 50% are expected to convert by the end of 2015.

Why Digital Printing Makes Too Much Sense to Ignore

Digital Printing is a Multi-Color Printing Process That Produces Photo-Quality Results

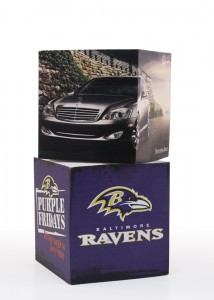

Traditional printing methods, such as spot color, have limitations. While there is no limit to the number of colors that can be spot printed, the restrictions come from the process itself. Digital printing, meanwhile, is a four color process (plus white), high definition 1200 dpi that is capable of hitting over 10,000,000 colors and fluid gradients to produce photo-quality images.

“Being digital, an almost endless array of process colors can be built using the cmyk+w spectrum,” said Matt Regan, CDigital senior vice president.

Digital printing also allows for the inclusion of variable data, such as barcodes, text, numbers, etc.

Digital Printing is Fast

With other decorating technologies, inks need to dry, solvents must be flamed off, or other curing processes need to take place, costing you time and money. Digital printing, meanwhile, is a fast, dry process.

These digital images are printed on the underside of a polyester film and coated with the proper adhesive for their destined substrate – metal, plastic, ceramics, etc. The film is then slit into various widths, wound on cardboard cores, and shipped to the customer.

Digital Printing is Affordable

The cost of setting up a traditional print run makes small quantity multicolor printing inefficient and cost-prohibitive. With digital printing, meanwhile, short run production is not only possible, but affordable.

“There are none of the traditional set-up requirements or costs,” explains Regan.

Digital Heat Transfers Offer Product Decorators the Benefits of Digital Printing

Since 2001, CDigital has been an innovator in developing new systems and processes for using digital print technology to produce full color digital heat transfers for the product decoration industry. Our print technology is by far the most cost effective full color print solution in the product decoration industry today.

If you have any questions about Digital Heat Transfers and the role of aesthetics in purchasing decisions, you can contact CDigital by calling 410-646-7800. You can also follow our Facebook, Twitter, Google+, Pintrest, and YouTube accounts for our latest news.